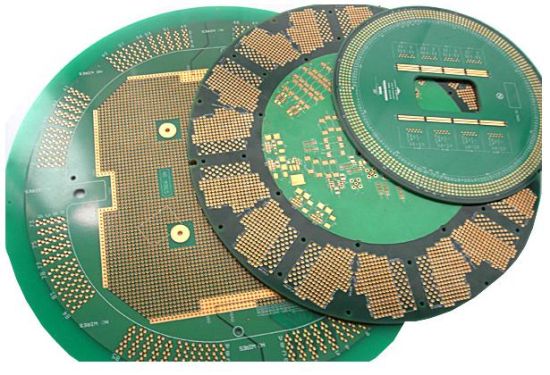

Designing a printed circuit board with 100 layers may be complex and involved. It is necessary to have an in-depth knowledge of the technical requirements, the materials, and the production processes involved. In this article, we will cover several best practices that will assist you in successfully creating a high-performance and dependable printed circuit board (PCB) and analyze the procedures involved in designing a 100-layer PCB.

Technical Considerations

To design a printed circuit board with 100 layers, one must have an in-depth knowledge of the technical needs and specifications of the project. The following are some essential things to keep in mind:

The integrity of the Signal

Signal integrity problems, such as crosstalk, noise, and impedance mismatch, may be caused by the high density of a printed circuit board with 100 layers. It is vital to employ high-quality materials, a suitable stack-up configuration, and sophisticated signal routing methods such as differential pairs and length matching to ensure excellent signal integrity. This may be accomplished by following these steps.

Power Integrity

To guarantee the highest possible level of power integrity, a PCB with 100 layers must put great thought into its power distribution network (PDN). To do this, the power plane must be optimized, suitable decoupling capacitors must be chosen, and the amount of noise and voltage drop must be reduced.

Management of Thermal Resources

A PCB with designing a 100-layer PCB has the potential to create a substantial amount of heat, which may hurt both the board’s performance and its dependability. It is necessary to use thermal vias, pads, and heat sinks to properly disperse the heat if one is interested in achieving optimum thermal management.

The Selection of Materials

The proper selection of materials is essential to effectively designing a 100-layer PCB. The following are some critical things to keep in mind:

Laminate Material

To guarantee the highest possible level of signal integrity, the laminate material used to construct a printed circuit board with one hundred layers has to be of high quality and have a low value for both the dielectric constant and the loss tangent.

Copper Foil

The copper foil used for the 100-layer PCB should be of excellent quality to achieve optimum power and signal performance. Moreover, it should have a low profile and good conductivity.

Conclusion

Designing a printed circuit board with 100 layers is complicated, and the designer must carefully consider several different manufacturing and technical variables. It is necessary to have an in-depth grasp of the technical requirements, materials, and manufacturing processes involved in designing a 100-layer PCB with any degree of success.

When creating a printed circuit board (PCB) with 100 layers, some best practices include optimizing the stack-up configuration, choosing the appropriate materials, utilizing advanced routing and testing techniques, partnering with an experienced PCB manufacturer, and performing exhaustive testing and validation. Following these best practices, you can effectively build a high-performance, dependable, and long-lasting 100-layer PCB for your application.